Yes, enhanced safety gear and practices can significantly reduce your chances of getting puncture wounds. Selecting the right materials, such as Kevlar for gloves and heavy-duty, puncture-resistant soles for shoes, is crucial. Incorporating steel toe caps further shields against heavy falling objects. Beyond gear, being vigilant in high-risk environments, conducting thorough risk assessments, and adopting safe handling and storage practices for sharp objects are vital. Training for hazard awareness and the correct use of protective equipment reinforces your defense against injuries. Each layer of precaution contributes to a safer environment, inviting a deeper exploration into safeguarding well-being.

Key Takeaways

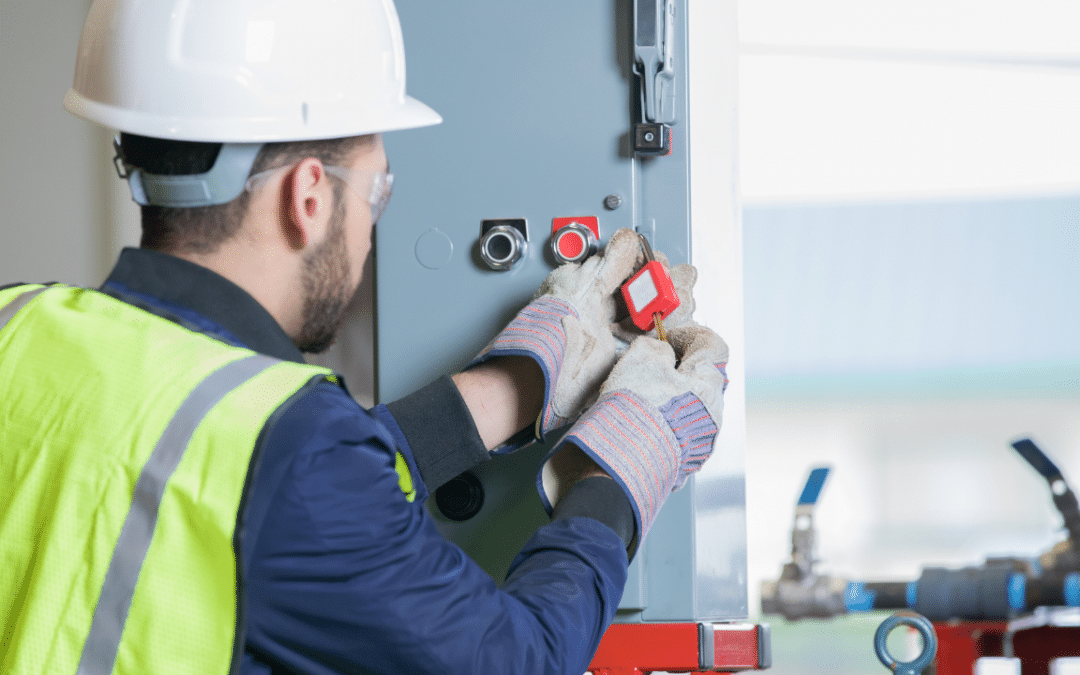

- Enhanced safety gear like Kevlar gloves and steel-toe footwear significantly reduces puncture wound risks.

- Proper training in hazard awareness and safe handling practices minimizes incidents.

- Regular risk assessments identify potential hazards, allowing for targeted preventive measures.

- Using puncture-resistant containers for storage and systematic organization reduces exposure to sharp objects.

- While greatly reduced, the risk of puncture wounds can’t be entirely eliminated due to unforeseen accidents and human error.

Understanding Puncture Wounds

Puncture wounds, often resulting from the penetration of sharp objects into the skin, pose significant risks due to their potential to introduce bacteria deep into the body’s tissues. You’re likely aware that these injuries can range from minor to severe, depending on the depth of penetration and the object involved. It’s crucial to understand that the nature of puncture wounds makes them more susceptible to infections than cuts or lacerations. This is because the entry point can close rapidly, trapping bacteria inside and making it harder for the wound to drain.

Research indicates that prompt and appropriate treatment significantly reduces the risk of complications. This includes thorough cleaning of the wound, sometimes tetanus prophylaxis, and in some cases, antibiotics. However, prevention is always preferable to treatment. Understanding the mechanics behind puncture wounds is vital for developing effective prevention strategies. For instance, knowing that stepping on a nail can drive bacteria deep into the foot highlights the importance of protective measures in high-risk environments.

Your role in serving others involves not just responding to these injuries but also educating about prevention and early intervention. By leveraging your knowledge and skills, you can significantly contribute to reducing the incidence and impact of puncture wounds within your community.

Importance of Safety Footwear

You must consider the impact of footwear material choices on mitigating puncture wound risks in hazardous environments.

Studies show that materials with higher puncture resistance significantly reduce injury rates.

Additionally, incorporating slip resistance features into safety footwear greatly minimizes the likelihood of accidents that could lead to such injuries.

Footwear Material Choices

Selecting the right material for safety footwear is crucial in protecting against puncture wounds in hazardous environments. Materials like Kevlar, known for its high tensile strength, offer excellent resistance to punctures, significantly reducing the risk of injuries from sharp objects.

Similarly, steel toe caps, while traditionally heavier, provide formidable protection against heavy falling objects, further safeguarding the feet. For those seeking a lighter alternative, composite materials, including carbon fiber, offer similar levels of protection without the added weight, enhancing mobility and comfort during prolonged use.

It’s essential to assess the specific hazards present in your work environment to choose the material that best meets your safety needs, ensuring you’re adequately protected while serving others in potentially dangerous situations.

Slip Resistance Features

Beyond protecting against punctures, safety footwear must also offer slip resistance, a critical feature for preventing falls in hazardous work environments. You’re likely aware that slips, trips, and falls constitute a significant portion of workplace accidents, often resulting in severe injuries or downtime.

Integrating slip-resistant features into safety footwear isn’t just a precaution; it’s a necessity for maintaining a secure working area. Research indicates that shoes with enhanced tread patterns significantly reduce the risk of slips on wet or oily surfaces. Moreover, materials like rubber and specific polymer blends have been identified for their superior grip and durability.

Hazard Awareness Training

You must recognize that identifying common risks in your environment plays a critical role in preventing puncture wounds. Studies show that workers trained in effective reporting protocols are significantly less likely to sustain injuries.

Thus, hazard awareness training isn’t just a formality; it’s a vital component of your safety strategy.

Identifying Common Risks

Understanding the common risks associated with puncture wounds is crucial for enhancing your safety in environments prone to such hazards. Environments with sharp objects, like construction sites or medical facilities, present significant risks. It’s essential to recognize that materials such as nails, needles, and even shattered glass can cause severe injuries if not handled with care.

Research indicates that most puncture wounds occur due to a lack of awareness or negligence towards potential hazards. By identifying these common risks and understanding their origins, you’re better equipped to implement preventive measures. This knowledge empowers you to serve others more effectively, ensuring a safer working environment for everyone involved.

Awareness is your first line of defense against the threat of puncture wounds.

Effective Reporting Protocols

In environments where the risk of puncture wounds is high, establishing and adhering to effective reporting protocols significantly reduces the likelihood of such injuries. These protocols aren’t just paperwork; they’re a critical safety net.

When you report a potential hazard or an actual incident promptly, you’re not just protecting yourself; you’re safeguarding your colleagues. This proactive approach is backed by evidence showing a direct correlation between prompt reporting and reduced injury rates.

It’s about creating a culture of transparency and responsibility. By doing so, you’re contributing to a safer workplace where everyone is aware of the risks and committed to mitigating them.

Protective Gloves: A Must-Have

Protective gloves serve as a critical barrier, significantly reducing the risk of puncture wounds in hazardous environments. In fields where the potential for injury is high, such as healthcare, construction, and manufacturing, the adoption of high-quality protective gloves is non-negotiable. You’re not just protecting yourself; you’re upholding a commitment to the safety and well-being of those around you.

Consider the following aspects of protective gloves that underline their importance:

- Material and Design: The choice of material—whether nitrile, latex, or Kevlar—plays a pivotal role in the level of protection offered. Gloves designed with reinforced layers offer enhanced resistance against sharp objects, effectively minimizing the risk of puncture wounds.

- Compliance with Safety Standards: Gloves that meet recognized safety standards ensure a baseline of protection. You’re not only investing in personal safety but also aligning with best practices that benefit everyone in the workspace.

- Proper Fit and Comfort: Gloves that fit well and offer comfort for extended wear encourage consistent use. A glove that’s too tight or too loose can compromise dexterity and protection, potentially increasing the risk of accidents.

Incorporating protective gloves into daily routines isn’t just about adhering to safety protocols; it’s a proactive step towards creating a safer environment for everyone involved.

Conducting Thorough Risk Assessments

Conducting thorough risk assessments is essential in identifying potential hazards that could lead to puncture wounds in the workplace. This proactive approach requires you to meticulously evaluate the work environment, tools, and materials that employees interact with daily. It’s not just about acknowledging the obvious risks but also uncovering hidden dangers that may not be immediately apparent.

You’ll begin by systematically cataloging all tasks and processes, paying special attention to those involving sharp objects or equipment that could puncture the skin. This detailed inventory serves as the foundation for your risk assessment. Next, you’ll analyze the frequency and severity of exposure to these hazards, which enables you to prioritize risks effectively.

Equipped with this knowledge, you’re better positioned to implement targeted safety measures. It’s crucial to involve employees in this process, as their firsthand experience offers invaluable insights into potential hazards and the effectiveness of existing safety protocols.

Safe Handling Practices

Adopting safe handling practices significantly reduces the risk of puncture wounds when interacting with sharp objects or equipment in the workplace. Your commitment to these practices not only ensures your well-being but also fosters a culture of safety that benefits everyone around you. By understanding and implementing evidence-based strategies, you’re taking a pivotal step towards virtually eliminating the risk of injuries.

Consider the following practices to create a safer working environment:

- Maintain Full Attention: Always focus on the task at hand when handling sharp objects. Distractions are a leading cause of accidents. Visualize your movements and the potential outcomes before proceeding.

- Use Protective Equipment: Gloves and other protective gear are your first line of defense. Ensure they’re appropriate for the specific task and in good condition. This simple step can drastically reduce the incidence of puncture wounds.

- Implement Proper Techniques: Learn and apply the correct techniques for handling, passing, and disposing of sharp objects. For example, never pass a sharp instrument directly to another person—place it down on a secure surface instead.

Storage Solutions for Sharp Objects

Effective storage solutions are critical in minimizing the risk of puncture wounds by ensuring sharp objects are securely and safely organized. You’re aware that the key to preventing accidents lies not only in how you handle sharp tools but also in how they’re stored when not in use. Let’s delve into the evidence-based strategies that cater to this need.

Firstly, utilizing containers that are puncture-resistant is non-negotiable. Studies have shown that containers made from materials such as thick plastic significantly reduce the risk of accidental puncture wounds. These containers should be clearly labeled and, whenever possible, color-coded to facilitate quick identification and minimize handling errors.

Secondly, implementing a designated storage area for sharp objects is imperative. This area should be out of reach of unauthorized persons, especially children, and organized in a manner that sharp ends aren’t exposed. A systematic approach to storage not only enhances safety but also increases efficiency in retrieving and returning items to their proper place.

Lastly, regular audits of storage practices are essential. This ensures that all safety protocols are being followed and that any new or temporary staff are fully trained in these critical safety measures.

Prevention Tips for Home and Workplace

Having explored storage solutions for minimizing puncture wound risks, it’s now important to focus on preventive measures that can be adopted both at home and in the workplace. Ensuring safety from puncture wounds requires a proactive approach, integrating both education and physical safeguards. The goal is to create environments where the likelihood of such injuries is vastly reduced.

Here are three prevention tips that stand out for their effectiveness:

- Regular Safety Training: You must prioritize regular safety training sessions. These sessions should cover the correct handling of sharp objects, emergency response procedures, and the importance of using protective gear. Empirical evidence suggests that consistent training can significantly decrease the incidence of workplace injuries.

- Implementation of Protective Gear: It’s crucial to wear the right protective gear. Gloves made from materials like Kevlar offer high resistance against punctures and cuts. For jobs with a higher risk, consider additional protective clothing that covers more vulnerable areas.

- Routine Safety Audits: Conducting periodic safety audits helps identify potential hazards before they result in injuries. These audits should assess both the physical environment and the practices being followed. Corrective actions should be promptly implemented based on audit findings.

Adopting these measures can significantly reduce the risk of puncture wounds, fostering a safer environment for everyone involved.

Frequently Asked Questions

How Does the Cost of Implementing Enhanced Safety Gear and Practices Compare to the Potential Medical and Legal Costs Associated With Puncture Wounds in the Workplace?

Investing in enhanced safety gear and practices might seem costly upfront, but you’ll likely save significantly on potential medical and legal expenses resulting from workplace puncture wounds. It’s a proactive approach that benefits everyone involved.

Can Psychological Factors, Such as Stress or Fatigue, Influence the Likelihood of Experiencing a Puncture Wound, Despite Adhering to Safety Practices?

You might think safety gear’s enough, but stress and fatigue can still raise your risk of puncture wounds. Research shows a clear link, highlighting the need for comprehensive safety that addresses psychological factors too.

What Are the Long-Term Health Implications of Puncture Wounds That Might Not Be Immediately Apparent, Including Potential Chronic Conditions or Disabilities?

Puncture wounds can lead to chronic conditions like nerve damage or infections, impacting your long-term health. It’s crucial you’re aware of these risks to better serve others by promoting preventive measures and timely treatment.

How Effective Are Natural or Alternative Remedies in Treating Puncture Wounds, and Are They a Viable Substitute for Traditional Medical Treatments?

You’re exploring whether natural remedies can effectively treat puncture wounds, and if they’re a good alternative to traditional treatments. Though some may offer benefits, they shouldn’t replace professional medical care, especially for serious injuries.

In What Ways Can Advancements in Technology, Such as Automation or Robotics, Reduce the Human Risk of Puncture Wounds in Industries Traditionally Prone to Such Injuries?

You might think automation’s too costly, but it’s a smart investment. By integrating robotics in hazardous environments, you’re significantly reducing the risk of puncture wounds, ensuring worker safety through precise, controlled operations. It’s about protecting your team.